Introduction to Self-Healing Concrete

Self-Healing Concrete is an innovative development in the field of civil engineering and material science, which combines biotechnology and construction. This concrete variant possesses the unique ability to self-heal, that is, to repair its own cracks. This is a significant advancement in construction, as it extends the lifespan of concrete structures and reduces maintenance costs. The self-healing property of this concrete is attributed to a unique biological process where certain bacteria embedded within the concrete produce limestone to seal any cracks that may form. This revolutionary material science innovation offers a sustainable solution to the common problem of concrete degradation, often caused by the penetration of harmful substances through cracks. The self-healing feature of this concrete enhances its durability, reduces environmental impact, and offers significant cost savings in the long run. It marks a new era in the construction industry where sustainability and efficiency are key. The potential applications of Self-Healing Concrete within civil engineering and infrastructure are vast. It can be used in residential and commercial buildings, bridges, tunnels, and roads. The advent of this self-healing material is set to revolutionize our understanding of concrete and its role in our built environment.

What is Self-Healing Concrete?

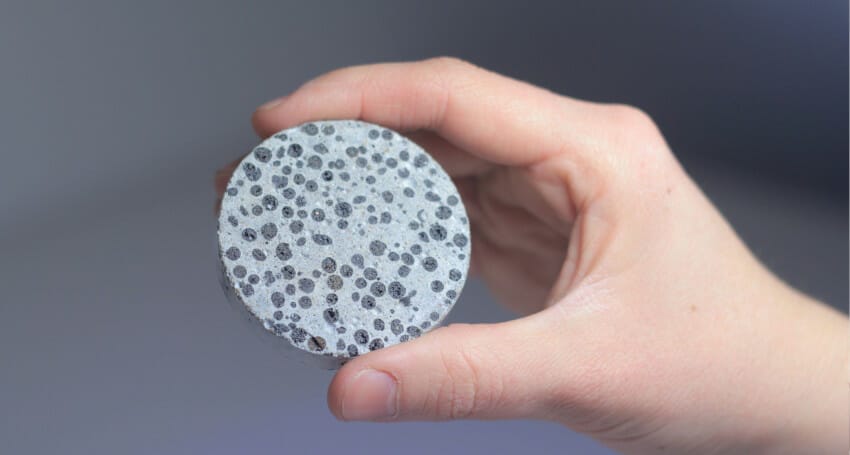

Self-Healing Concrete is a type of concrete that has been engineered to repair its own cracks, a significant advancement in the field of material science and civil engineering. This unique characteristic is achieved by incorporating specific bacteria within the concrete mix. These bacteria, when exposed to water and oxygen — elements that usually penetrate concrete through cracks — initiate a biological reaction that leads to the production of limestone. This limestone then fills the cracks, effectively sealing them and preventing further damage. This biological process is entirely natural and does not require any human intervention, making Self-Healing Concrete an extremely efficient and sustainable solution for concrete structures. The bacteria used in this biotechnology process are encapsulated in microcapsules or embedded in porous particles to ensure their survival during the mixing and setting of the concrete. The self-healing ability of this concrete can significantly enhance the lifespan of structures, reduce maintenance costs, and minimize the environmental footprint of construction activities. It is a breakthrough in the field of construction materials, offering a sustainable and efficient alternative to traditional concrete.

The History of Self-Healing Concrete

The concept of Self-Healing Concrete was first introduced in the early 21st century by a team of microbiologists and civil engineers at Delft University of Technology in the Netherlands. The team was led by Hendrik Jonkers, who was inspired by the natural healing ability of the human body. His vision was to develop a concrete material that could mimic this self-healing process. The team experimented with various types of bacteria, eventually settling on a specific type known as Bacillus Pseudofirmus and Sporosarcina Pasteurii. These bacteria are highly alkaline-resistant and can survive in the harsh environment of concrete for up to 200 years. They are activated when water enters the concrete’s cracks, initiating the production of limestone that seals the cracks. Since its inception, the technology of Self-Healing Concrete has been progressively refined and improved. It has been tested and implemented in various construction projects around the world, demonstrating its effectiveness and potential. This innovative material represents a significant step forward in sustainable construction, paving the way for more resilient and durable structures in the future.

Why is Self-Healing Concrete a Vision for the Construction Industry?

Self-healing concrete, a groundbreaking development in the field of material science and civil engineering, is seen as the future of the construction industry. This innovative concrete has the potential to significantly decrease maintenance costs and enhance the lifespan of infrastructure, making it a sought-after solution in the construction sector. The unique self-healing properties of this concrete are its ability to autonomously repair its own cracks and faults, which reduces the need for frequent maintenance. This feature not only cuts down on maintenance costs but also extends the longevity of structures, contributing to sustainability in the construction industry. The environmental benefits of self-healing concrete are significant. Traditional concrete production is a major contributor to global CO2 emissions. By reducing the need for frequent repairs and replacements, self-healing concrete can help mitigate these environmental impacts, promoting sustainability in the construction industry.

Mechanisms of Self-Healing Concrete

Self-healing concrete employs the principles of biotechnology, using bacteria within the concrete mix to facilitate healing. These bacteria, when exposed to water and oxygen, produce limestone, which effectively seals any cracks that form in the concrete. This process is entirely autonomous and does not require any human intervention. The bacterial action is facilitated by the inclusion of calcium lactate within the concrete mix. When water infiltrates the concrete, it dissolves the calcium lactate, which is then consumed by the bacteria. The limestone produced as a byproduct of this consumption fills in the cracks, restoring the integrity of the concrete structure. The bacteria used in self-healing concrete belong to the Bacillus genus, known for their hardiness and longevity. These bacteria can survive in the harsh environment of concrete for decades, ensuring the self-healing properties of the concrete for the duration of its expected lifespan.

How Does Self-Healing Concrete Work?

The process of self-healing in concrete begins when a crack forms. Water infiltrates the crack, dissolving the calcium lactate present in the concrete mix. This dissolved calcium lactate then serves as a nutrient source for the bacteria within the concrete. Upon consuming the calcium lactate, the bacteria produce limestone as a byproduct. This limestone then fills in the crack, effectively sealing it and restoring the structural integrity of the concrete. This process occurs autonomously, without the need for human intervention. The self-healing process can occur repeatedly, as long as there are sufficient bacteria and calcium lactate within the concrete. This ensures the longevity of the self-healing properties of the concrete, making it a highly durable and cost-effective material for construction projects.

Exploring Autogenous Healing

Autogenous healing, an intrinsic characteristic of concrete, is a self-repair mechanism that material science and civil engineering fields have recognized as a natural phenomenon. This process occurs without external intervention when water interacts with unhydrated cement particles within the concrete matrix. The water-cement reaction results in the formation of calcium silicate hydrate and calcium carbonate, which precipitate and fill the cracks, contributing significantly to the sustainability of concrete infrastructure. The effectiveness of autogenous healing in concrete, a key topic in material science and civil engineering, is influenced by several factors. These include the width of the cracks, the availability of water, and the presence of unhydrated cement particles. Narrow cracks tend to heal more effectively as the precipitated minerals can bridge the gap more easily. Furthermore, the availability of water is crucial for the hydration reaction to occur, while the presence of unhydrated cement particles provides the necessary materials for the formation of the healing compounds. Despite its benefits, autogenous healing has its limitations. The process is only effective for very small cracks, typically less than 0.2 millimeters in width. Moreover, the availability of unhydrated cement particles and water is often limited in mature concrete, reducing the potential for autogenous healing. Therefore, while autogenous healing can contribute to the durability and longevity of concrete structures, it is not sufficient to address all forms of concrete damage.

Stimulated Autogenous Healing and Its Techniques

Stimulated autogenous healing, a strategy that enhances the natural autogenous healing ability of concrete, is of significant interest in construction and material science. This approach aims to overcome the limitations of autogenous healing, particularly its inability to heal larger cracks and its dependence on the availability of unhydrated cement particles and water. One common technique in the construction industry is the use of supplementary cementitious materials, such as fly ash, silica fume, and blast furnace slag. These self-healing materials can increase the quantity of unhydrated cement particles in the concrete, providing more material for the formation of healing compounds. Additionally, they can reduce the permeability of the concrete, limiting the size of the cracks that can form. Another technique involves the incorporation of expansive agents into the concrete mix. These agents can induce controlled expansion of the concrete, helping to close and heal the cracks. However, the use of expansive agents requires careful design and control to prevent excessive expansion, which could lead to further cracking.

Overview of Autonomous Self-Healing

Autonomous self-healing concrete is an innovative technology that integrates self-healing mechanisms into the concrete mix design. This approach aims to create concrete structures that can autonomously repair their own cracks, improving their durability and reducing maintenance costs. The autonomous self-healing mechanisms can be classified into two main categories: intrinsic and extrinsic. Intrinsic mechanisms, such as autogenous healing and stimulated autogenous healing, rely on the inherent properties of the concrete and its components. Extrinsic mechanisms, on the other hand, involve the incorporation of healing agents into the concrete. These agents can be released into the cracks, where they react with the concrete or with each other to form healing compounds. Despite its promising potential, autonomous self-healing concrete faces several challenges. These include the need for effective delivery systems for the healing agents, the compatibility of the healing agents with the concrete, and the cost-effectiveness of the technology. Nevertheless, with ongoing research and development, autonomous self-healing concrete represents a promising solution for enhancing the durability and sustainability of concrete structures.

Effectiveness and Performance of Self-Healing Concrete

Self-healing concrete, a groundbreaking innovation in the field of construction and civil engineering, has shown considerable potential in enhancing the durability and lifespan of infrastructure. This concrete, embedded with bacteria or activated by chemical reactions, is capable of autonomously repairing its own cracks, up to 0.8mm in width. This self-healing property significantly reduces the need for maintenance work, thereby increasing the longevity of concrete structures. In terms of performance, self-healing concrete has demonstrated resilience under significant stressors, maintaining its structural integrity even in harsh environmental conditions. It is particularly effective in infrastructure exposed to heavy loads, corrosive substances, or extreme weather. However, comprehensive research is still required to fully understand the long-term performance of self-healing materials under various environmental stressors. From a sustainability perspective, self-healing concrete could substantially reduce the environmental impact of the construction industry. By extending the lifespan of concrete structures and minimizing the need for replacement, this material could contribute to reducing the industry’s carbon footprint. However, the production process of self-healing concrete, which involves significant energy and resource consumption, must be factored into its overall environmental impact assessment.

How Effective Is Self-Healing Concrete?

The effectiveness of self-healing concrete largely depends on its specific formulation and the conditions in which it is applied. Laboratory tests have shown that self-healing concrete can autonomously seal cracks up to 0.8mm wide within a few weeks, a significant improvement over traditional concrete. However, the real-world effectiveness of self-healing materials is still under investigation. Preliminary field tests have shown promising results, but further research is needed to corroborate these findings and optimize the performance of self-healing concrete under varying conditions. The size and location of the cracks, the presence of moisture, and the temperature can all influence the effectiveness of self-healing concrete. These factors can affect the activation of the self-healing mechanism and the speed at which the cracks are sealed. Therefore, understanding these variables is crucial for optimizing the effectiveness of self-healing materials in the field of construction and civil engineering.

Key Influential Factors of Self-Healing

Several factors can influence the effectiveness of self-healing in concrete. The size of the cracks is a crucial factor; self-healing concrete has been shown to effectively seal cracks up to 0.8mm in width, but larger cracks may not be fully repaired. This is due to the self-healing mechanism’s reliance on the diffusion of bacteria or chemicals through the concrete, a process that can be impeded by large cracks. Moisture is another key element influencing self-healing. The self-healing process in concrete is activated by water, meaning that the concrete must be exposed to moisture for the self-healing process to occur. However, excessive moisture can dilute the bacteria or chemicals, reducing their effectiveness. Temperature also plays a critical role in the self-healing process. The bacteria or chemicals used in self-healing materials are sensitive to temperature, and their activity can be significantly reduced in very cold or very hot conditions. Therefore, the effectiveness of self-healing concrete can vary depending on the climate in which it is used. Lastly, the composition of the concrete itself can influence the effectiveness of the self-healing process. The type and quantity of bacteria or chemicals used, the size and distribution of the pores in the concrete, and the presence of other additives can all affect the self-healing mechanism. These factors underscore the importance of material science in the development and application of self-healing materials in the construction industry.

Conclusion

In conclusion, Self-Healing Concrete represents a groundbreaking innovation in the field of civil engineering and material science. Its autonomous repair mechanism, which seals cracks through a unique biological process or chemical reactions, holds immense potential to revolutionize the construction industry. By enhancing the durability and lifespan of concrete structures, this innovative material can significantly reduce maintenance costs and minimize environmental impact. Moreover, it offers a sustainable solution to the common problem of concrete degradation, making it a promising alternative to traditional concrete. However, further research is needed to optimize its effectiveness under varying conditions and fully understand its long-term performance. Despite these challenges, the advent of Self-Healing Concrete marks a significant stride towards sustainable construction practices, paving the way for more resilient and durable infrastructure in the future.